23 Horizontal Injection Molding Machines

Horizontal injection molding machines are used in manufacturing to produce plastic parts by injecting molten plastic into a mold. These machines operate horizontally, allowing for the efficient production of a wide range of parts. They are popular for their speed, versatility, and ability to create detailed and complex shapes.

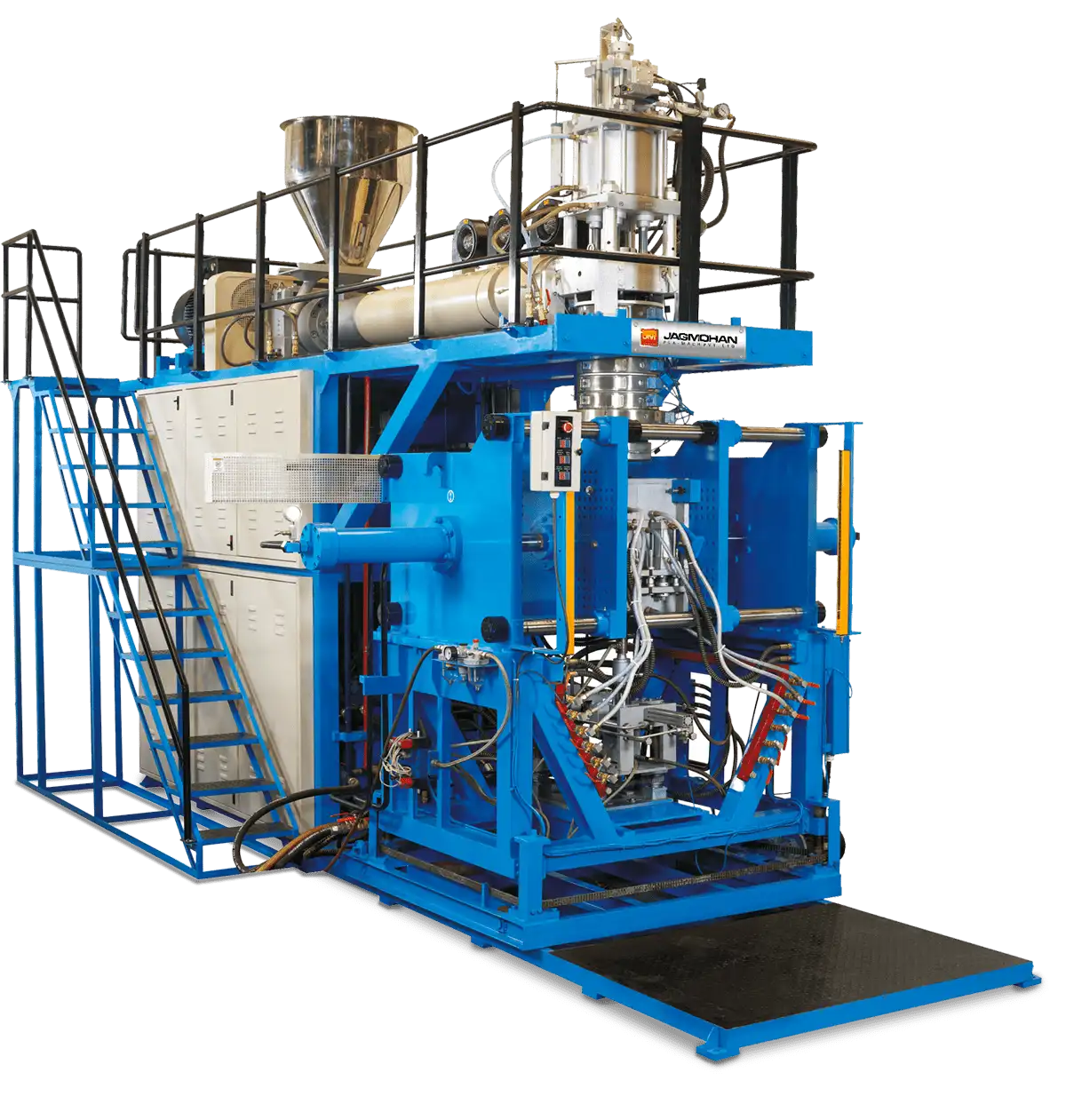

4 Extrusion Blow Molding Machines

Extrusion blow molding machines are used to create hollow plastic products, such as bottles and containers. The process involves extruding a tube of molten plastic, called a parison, and then inflating it within a mold to form the desired shape. These machines are ideal for producing lightweight, uniform items.

6 vertical Injection molding Machines

Vertical injection molding machines are designed with a vertical clamp and injection unit, ideal for insert molding and overmolding processes. They allow for easy loading of inserts and can handle smaller production spaces. These machines are efficient for manufacturing small parts, intricate designs, and products requiring embedded components.

Mig Welding

MIG welding, or Metal Inert Gas welding, is a process that uses a continuous wire electrode fed through a welding gun to join metals. Shielding gas, typically argon or a mix of gases, protects the weld pool from contamination. MIG welding is versatile, efficient, and widely used for various materials and thicknesses.

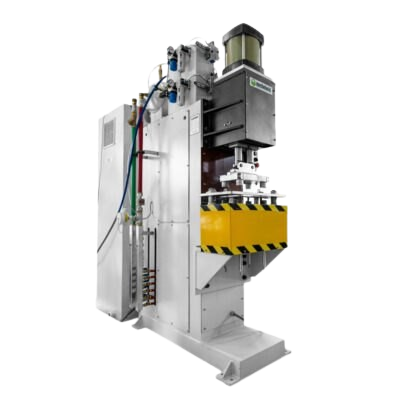

Projection welding Machine

Projection welding machines are specialized for joining metal components with pre-formed projections or embossments. The process involves applying electrical current and pressure through electrodes, causing the projections to heat and fuse with the mating part. This method is ideal for welding multiple points simultaneously and is commonly used for fasteners, nuts, and bolts.

Fan balancing Machine

Fan balancing machines are used to detect and correct imbalances in rotating fan blades. The machine measures vibration and identifies weight distribution issues, allowing for precise adjustments to ensure smooth operation. Proper balancing reduces noise, increases efficiency, and extends the lifespan of fans by minimizing wear and tear on components.

Fan balancing Machine

Fan balancing machines are used to detect and correct imbalances in rotating fan blades. The machine measures vibration and identifies weight distribution issues, allowing for precise adjustments to ensure smooth operation. Proper balancing reduces noise, increases efficiency, and extends the lifespan of fans by minimizing wear and tear on components.

Ring & Pipe Bending Machines

Ring and pipe bending machines are designed to bend pipes, tubes, and rings into various shapes and angles without compromising material integrity. They use mechanical or hydraulic force to achieve precise bends, ideal for manufacturing components in construction, automotive, and aerospace industries. These machines enable consistent, accurate bending with minimal deformation.

Fan balancing Machine

Fan balancing machines are used to detect and correct imbalances in rotating fan blades. The machine measures vibration and identifies weight distribution issues, allowing for precise adjustments to ensure smooth operation. Proper balancing reduces noise, increases efficiency, and extends the lifespan of fans by minimizing wear and tear on components.