Mon - Sat: 9:00 AM - 9:00 PM

Mon - Sat: 9:00 AM - 9:00 PM

Goel Enterprises was established in 1984 by Mr. Gireesh Goel (Proprietor) as an independent manufacturing unit in Chandigarh, India. Our organization is IATF 16949:2016 registered, specializing in Plastic Injection, Blow Molding, and the in-house assembly of Farm Equipment for the Automotive Industry and OEM (Original Equipment Manufacturer) applications.

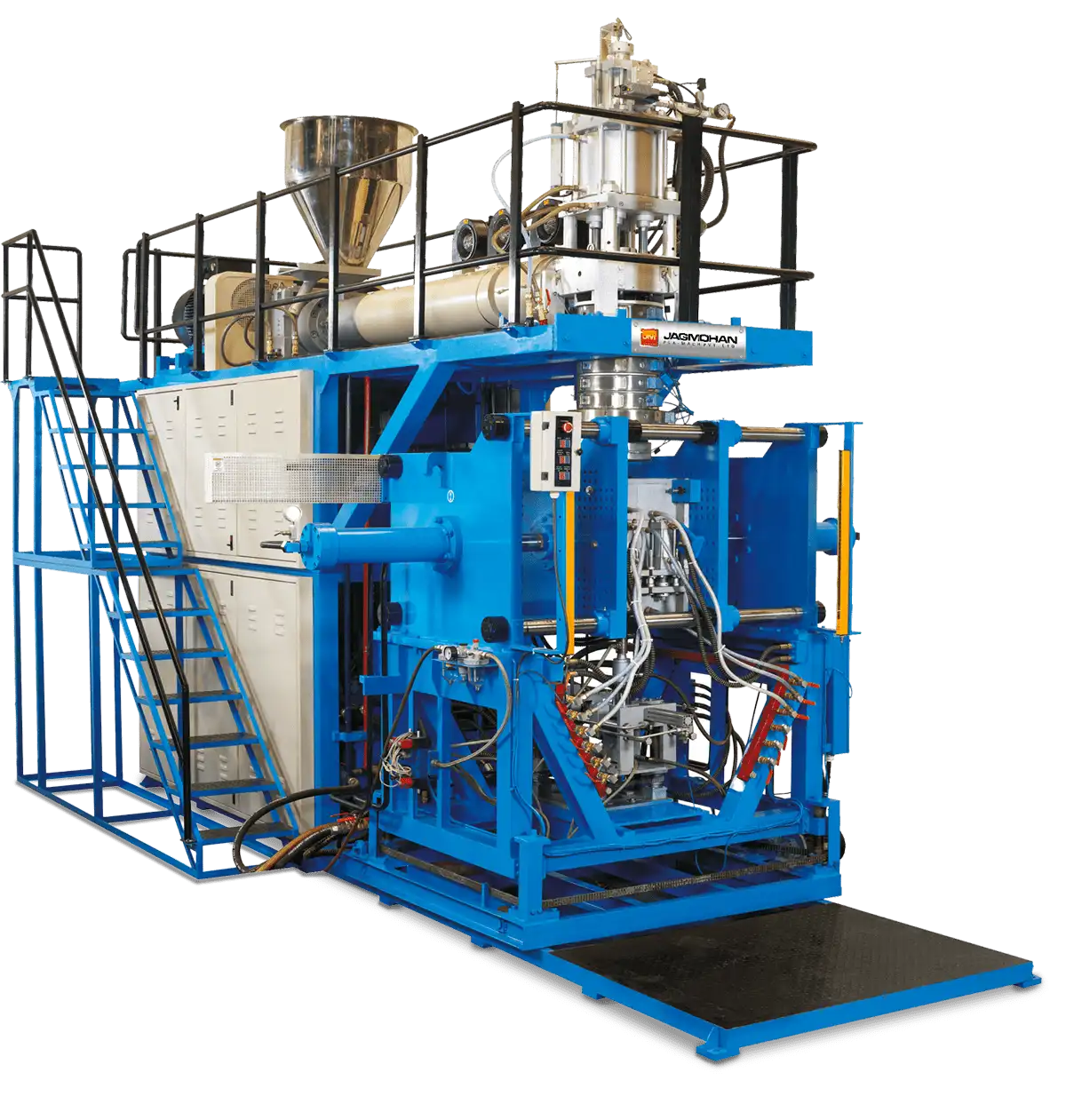

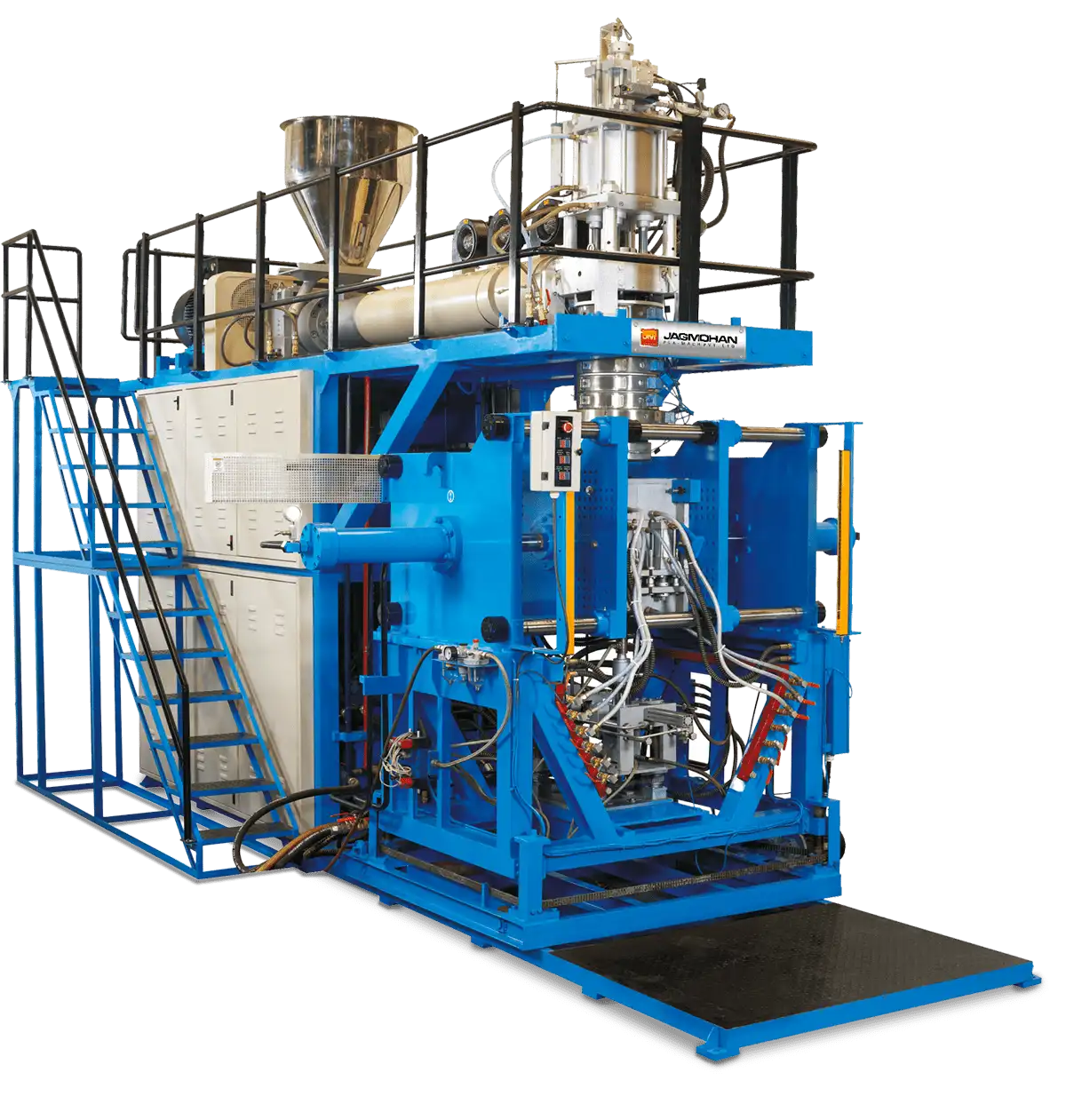

Operating from two units located in Chandigarh and Mohali, Goel Enterprises caters to a diverse clientele ranging from heavy automobile manufacturers to automotive vibration control technologists across the country. Our facilities are equipped with a Complete Injection Molding Shop featuring 23 Horizontal Injection Molding Machines, 6 Vertical Injection Molding Machines, and 4 Extrusion Blow Molding Machines. We also have multiple assembly units, a fabrication shop, and a tool manufacturing and maintenance facility. This comprehensive setup allows us to deliver top-notch services and products consistently.

Our journey began with a small-scale setup, but through relentless dedication and innovation, we have grown exponentially. Today, Goel Enterprises spans over a 40,000 sq ft facility, embodying our commitment to excellence and customer satisfaction. Our extensive experience in the industry enables us to offer tailored solutions that meet the specific needs of each client, ensuring that they receive the best possible products and services.

Our dedicated team ensures that all individual areas are meticulously managed, guaranteeing that you receive the best services every time. With a robust Quality Assurance department, we are committed to delivering only the highest quality products to our esteemed customers. Our in-house capabilities extend beyond manufacturing to include design and development, providing a one-stop solution for all your plastic molding needs.

At Goel Enterprises, we believe in continuous improvement and staying ahead of industry trends. We invest in the latest technologies and training for our team to ensure that we remain at the forefront of innovation. Our customer-centric approach means that we work closely with our clients, understanding their unique requirements and delivering solutions that drive their success.

Our mission is to provide superior plastic molding components and technical services, exceeding customer expectations through continuous innovation, quality standards, and process improvements.

To be a global leader in plastic molding solutions, renowned for our quality, innovation, and commitment to customer satisfaction.

Projects Completed

Expeart Engeneers

Awards Win

World Wide

Goel Enterprises was established in 1984 by Mr Gireesh Goel (Prop.) as an independent manufacturing unit in Chandigarh, India. We are specialized in Plastic Injection, Blow Molding and In-house assembly of Farm Equipment's, Automotive Industry for OEM.

Initiated operations with the manufacturing of Gear Shifter Knobs, Fuel Cut Off Knobs, and Throttle Knobs in Compression Bacolite Molding.

Advanced into producing larger plastic molding parts like Head Light Plates and Radiator Fans.

Developed a range of injection molding plastic parts including Tool Boxes, Panels, Mobile Boxes, Mud Guards, and more.

Added three extrusion blow molding machines with a capacity of up to 100 liters, significantly boosting our production volume.

Grew our product lines to over 50 for extrusion blow molding, serving the farm and automotive sectors extensively.

Ventured into the production of dashboards cluster for passenger vehicles, diversifying our product offerings.

From 2024 onward, we are focused on developing new product lines, embracing innovation, and driving growth and expansion. Our commitment to quality and customer satisfaction will continue to guide us as we explore new opportunities and enhance our capabilities. We strive to maintain the highest standards of service and quality, firmly believing in getting it right the first time.

Began production of electrical components such as Hazard Switches, Fuse Box Assemblies, and Flasher Switch Assemblies instrument panel.

Launched the steering wheels designed by GE with integrated horn assembly, marking a radical innovation in our product line and contributed significantly to the company's growth.

Incorporated the extrusion blow molding process developing the no loss tank into our factory operations, enhancing our range of production capabilities.

Expanded into the manufacturing of precision plastic parts such as plastic fasteners and grommets for the automotive and medical industry.

.webp)

Acquired a 1100-tonnage injection molding machine, the highest tonnage machine in the Tri-city area, to further our manufacturing capabilities.

Expanded our manufacturing area to 40,000 sq. ft, enhancing our production and operational efficiency.

Installed a new extrusion blow molding machine to augment our existing production capacity.

Goel Enterprises was established in 1984 by Mr Gireesh Goel (Prop.) as an independent manufacturing unit in Chandigarh, India. We are specialized in Plastic Injection, Blow Molding and In-house assembly of Farm Equipment's, Automotive Industry for OEM.

Initiated operations with the manufacturing of Gear Shifter Knobs, Fuel Cut Off Knobs, and Throttle Knobs in Compression Bacolite Molding.

Began production of electrical components such as Hazard Switches, Fuse Box Assemblies, and Flasher Switch Assemblies instrument panel.

Advanced into producing larger plastic molding parts like Head Light Plates and Radiator Fans.

Launched the steering wheels designed by GE with integrated horn assembly, marking a radical innovation in our product line and contributed significantly to the company's growth.

Developed a range of injection molding plastic parts including Tool Boxes, Panels, Mobile Boxes, Mud Guards, and more.

Incorporated the extrusion blow molding process developing the no loss tank into our factory operations, enhancing our range of production capabilities.

Added three extrusion blow molding machines with a capacity of up to 100 liters, significantly boosting our production volume.

Expanded into the manufacturing of precision plastic parts such as plastic fasteners and grommets for the automotive and medical industry.

Grew our product lines to over 50 for extrusion blow molding, serving the farm and automotive sectors extensively.

.webp)

Acquired a 1100-tonnage injection molding machine, the highest tonnage machine in the Tri-city area, to further our manufacturing capabilities.

Expanded our manufacturing area to 40,000 sq. ft, enhancing our production and operational efficiency.

Ventured into the production of dashboards cluster for passenger vehicles, diversifying our product offerings.

Installed a new extrusion blow molding machine to augment our existing production capacity.

From 2024 onward, we are focused on developing new product lines, embracing innovation, and driving growth and expansion. Our commitment to quality and customer satisfaction will continue to guide us as we explore new opportunities and enhance our capabilities. We strive to maintain the highest standards of service and quality, firmly believing in getting it right the first time.

Engineer

Engineer

Engineer

Engineer

Engineer